The article highlights the key points related to the regulatory status of the products in question and describes the approach to be followed.

Table of Contents

The Food and Drug Administration (FDA or the Agency), the US regulating authority in the sphere of healthcare products, has published a guidance document dedicated to the technical considerations for medical devices with physiologic closed-loop control (PCLC) technology.

The document provides an overview of the applicable regulatory requirements set forth under the existing legal framework, as well as additional clarifications and recommendations to be taken into consideration by medical device manufacturers and other parties involved in order to ensure compliance thereto.

At the same time, provisions of the guidance are non-binding in their legal nature, nor are they intended to introduce new rules or impose new obligations.

Moreover, the authority explicitly states that an alternative approach could be applied, provided such an approach is in line with the respective legislation and has been agreed with the authority in advance.

The present document constitutes a final version of the guidance based on the draft initially issued earlier in December 2021.

Introduction and Importance of PCLC Devices

In accordance with the guidance, a Physiologic Closed-Coop Controlled (PCLC) device consists of sensors, actuators, and control algorithms.

Its primary function is to adjust or regulate a physiologic variable using feedback from a sensor, allowing for the automatic delivery or removal of energy or articles, such as drugs or medical liquids/gases.

This sophisticated technology holds the potential to enhance the automation capabilities of various medical devices.

Such automated devices can revolutionize healthcare by ensuring timely, precise, and consistent treatment.

Additionally, they can significantly reduce cognitive overload on medical professionals, diminish the margin of human error, and augment medical response in emergency situations.

However, together with their potential, it is also important to prioritize patient safety in evaluating the benefits of PCLC devices.

This document outlines the technical considerations essential for the safe and effective development of PCLC medical devices. Moreover, it provides guidelines for their premarket submissions.

Background: Automation and its Advantages

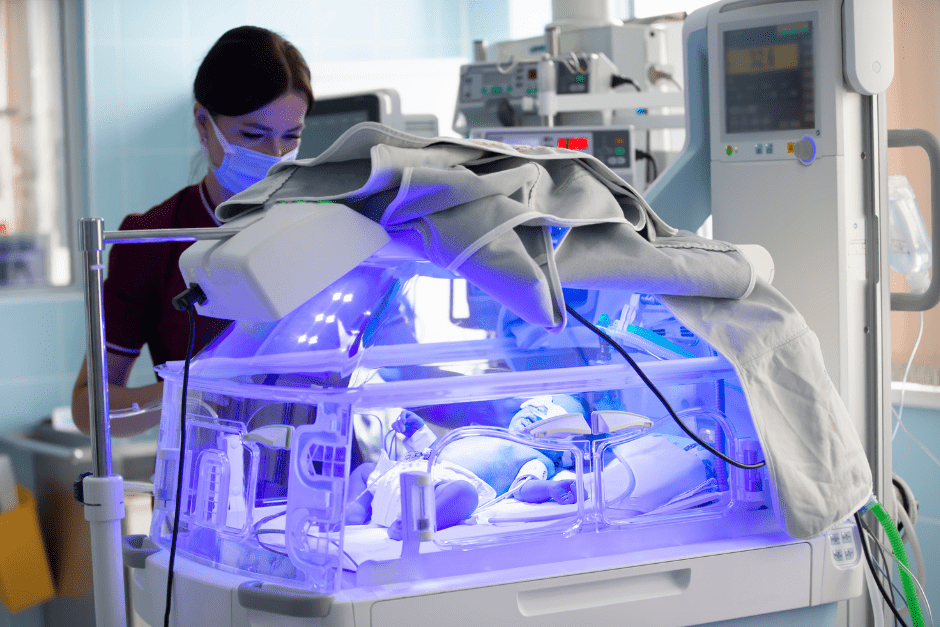

PCLC devices employ control system technology typically found in host medical devices like infusion pumps, ventilators, and extracorporeal systems.

They ensure safe, consistent, and timely delivery or removal of energy or articles.

This can significantly improve the quality and accuracy of treatment delivery, mitigate the risks of under- or overdosing, and provide a safer alternative when manual control proves to be challenging or unsuitable.

Moreover, these devices can alleviate the workload of caregivers, allowing them to redirect their focus to other pivotal aspects of patient care.

Despite the multiple advantages, automating devices and minimizing clinician intervention can present potential hazards if not designed or evaluated correctly. Issues such as algorithm defects, a lack of operational transparency, and automation biases might lead to automation-induced hazards.

The Center for Devices and Radiological Health (CDRH) has previously engaged in discussions around the design and evaluation considerations of PCLC devices, aiming to foster a collaborative environment with medical device manufacturers and clinical users.

Scope: Designing and Evaluating PCLC Devices

This guidance emphasizes the technical aspects of PCLC technology in the design of medical devices.

According to the document, PCLC devices can cover a wide range of functions, each with its unique risks.

Given the diversity of devices that can employ PCLC technology, it is up to the manufacturers to determine and justify the considerations suitable for their specific device during premarket submissions.

To provide clarity, the document outlines examples of PCLC technology applications:

- Anesthesia gas machines adjust in response to an end-tidal gas measurement or EEG signals.

- Mechanical ventilators adjust settings based on patient oxygen saturation or exhaled gas concentration.

- Systems that adjust drug infusion rates depending on the patient’s blood pressure.

- Insulin delivery systems operate based on blood glucose values.

- Systems modulating temperature in response to the patient’s body temperature.

International standards provide more exhaustive lists and distinctions between devices that employ PCLC technology and those that do not.

If there are ambiguities regarding whether a device qualifies as a PCLC device, manufacturers can seek clarity through the Q-Submission process described in detail in a separate guidance document issued by the FDA.

While this guidance provides general recommendations, it acknowledges that certain active implantable devices with PCLC technology might require additional considerations.

In instances where there are device-specific guidances available, those should be prioritized.

Manufacturers should apply the technical recommendations in this document to various premarket device-related submissions, including premarket notifications, De Novo Requests, Premarket Approval (PMA) applications, and Humanitarian Device Exemptions (HDE).

However, the specific premarket submission framework to be applied depends on the device’s classification, its associated risk, and necessary regulatory controls.

While many recommendations in this document can support the safety of a PCLC device in an Investigational Device Exemption (IDE), the design and testing will vary based on multiple factors such as the method of control algorithm design, properties of the delivery system, and more.

Furthermore, this guidance does not elaborate on the machine-learning aspects of a PCLC device’s design.

Thus, for such detailed feedback or specific recommendations, the authority encourages medical device manufacturers to utilize the Q-Submission process.

Scope: Designing and Evaluating PCLC Devices

This guidance emphasizes the technical aspects of PCLC technology in the design of medical devices.

According to the document, PCLC devices can cover a wide range of functions, each with its unique risks.

Given the diversity of devices that can employ PCLC technology, it is up to the manufacturers to determine and justify the considerations suitable for their specific device during premarket submissions.

To provide clarity, the document outlines examples of PCLC technology applications:

- Anesthesia gas machines adjust in response to an end-tidal gas measurement or EEG signals.

- Mechanical ventilators adjust settings based on patient oxygen saturation or exhaled gas concentration.

- Systems that adjust drug infusion rates depending on the patient’s blood pressure.

- Insulin delivery systems operate based on blood glucose values.

- Systems modulating temperature in response to the patient’s body temperature.

International standards provide more exhaustive lists and distinctions between devices that employ PCLC technology and those that do not.

If there are ambiguities regarding whether a device qualifies as a PCLC device, manufacturers can seek clarity through the Q-Submission process described in detail in a separate guidance document issued by the FDA.

While this guidance provides general recommendations, it acknowledges that certain active implantable devices with PCLC technology might require additional considerations.

In instances where there are device-specific guidances available, those should be prioritized.

Manufacturers should apply the technical recommendations in this document to various premarket device-related submissions, including premarket notifications, De Novo Requests, Premarket Approval (PMA) applications, and Humanitarian Device Exemptions (HDE).

However, the specific premarket submission framework to be applied depends on the device’s classification, its associated risk, and necessary regulatory controls.

While many recommendations in this document can support the safety of a PCLC device in an Investigational Device Exemption (IDE), the design and testing will vary based on multiple factors such as the method of control algorithm design, properties of the delivery system, and more.

Furthermore, this guidance does not elaborate on the machine-learning aspects of a PCLC device’s design.

Thus, for such detailed feedback or specific recommendations, the authority encourages medical device manufacturers to utilize the Q-Submission process.

Conclusion

The present FDA guidance outlines the key considerations related to the regulatory status of PCLC devices based on their specific nature. The document also provides an overview of their advantages and potential risks associated thereto.

How Can RegDesk Help?

RegDesk is a holistic Regulatory Information Management System that provides medical device and pharma companies with regulatory intelligence for over 120 markets worldwide. It can help you prepare and publish global applications, manage standards, run change assessments, and obtain real-time alerts on regulatory changes through a centralized platform. Our clients also have access to our network of over 4000 compliance experts worldwide to obtain verification on critical questions. Global expansion has never been this simple.