The document provides an overview of the EtO regulatory status and highlights the key points to be taken into consideration by the medical device manufacturers utilizing it in their processes.

Table of content

The Medical Device Coordination Group (MDCG) has published a guidance document dedicated to the regulatory status of ethylene oxide (EtO) intended for the sterilization of medical devices. The document provides an overview of the applicable regulatory requirements, as well as additional clarifications and recommendations to be taken into consideration by medical device manufacturers and other parties involved in order to ensure compliance.

At the same time, provisions of the guidance are non-binding in their legal nature, nor are they intended to introduce new rules or impose new obligations, and could also be subject to changes, should it be reasonably necessary to reflect corresponding amendments to the underlying legislation.

Introduction

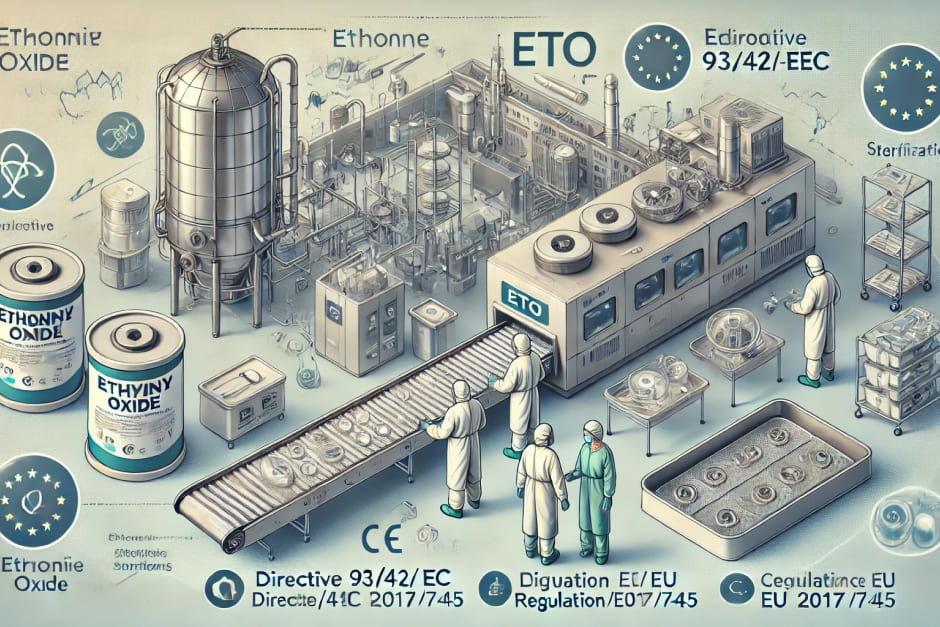

Ethylene oxide (EtO) plays a crucial role in sterilizing a wide range of medical products, including medical devices, in vitro diagnostic medical devices (IVDs), and medicinal products. It is used as part of the manufacturing process for products requiring sterile conditions and is applied in large-scale industrial units either by manufacturers or external sterilization providers.

Additionally, EtO is supplied in smaller cartridges for sterilization purposes in healthcare institutions, primarily for reusable medical devices. These cartridges are generally CE-marked under Directive 93/42/EEC or the current Regulation (EU) 2017/745 (MDR).

The regulatory landscape for EtO is significantly shaped by its role in ensuring compliance with sterilization requirements under various EU regulations.

Regulatory Status of EtO for Medical Device Sterilisation

As it was mentioned before, EtO is widely employed in the production of sterile medical devices and IVDs. The sterilization process is an integral part of Quality Management Systems (QMS) implemented by medical device manufacturers, as mandated by Article 10(9) MDR and Article 10(8) IVDR.

Compliance with these requirements involves:

- Sterilisation Process Validation: Detailed in harmonized standards such as EN ISO 13485:2016, which outlines quality management requirements for medical devices.

- General Safety and Performance Standards: Specific sections of Annex I in MDR and IVDR (e.g., 11.3–11.6 and 11.2–11.4) require adherence to harmonized standards for sterilization, including:

- EN ISO 11135:2014+A1:2019: Guidelines for developing, validating, and routinely controlling EtO sterilization processes for medical devices.

- EN ISO 10993-7:2008 + AC:2009 + A1:2022: Standards for evaluating biological residues of EtO sterilization.

- EN 556-1:2024: Requirements for terminally sterilized medical devices to be labeled “STERILE”.

- Technical Documentation: Required under Annex II MDR/IVDR to demonstrate conformity.

- Qualification of Notified Body Personnel: As specified in Annex VII, sections 3.2.1 and 3.2.5 of the MDR/IVDR.

- Conformity Assessment Procedures: Detailed in Annex IX and XI, governing aspects such as sterilization process validation.

While EtO itself does not qualify as a medical device under MDR/IVDR definitions, its use in the sterilization process falls within the regulatory scope of these frameworks. Consequently, EtO for manufacturing sterilization is exempt from the Biocidal Products Regulation (BPR) under Article 2(2)(b).

This exemption applies because the sterilization process is controlled under MDR/IVDR conformity assessments, eliminating the need for separate evaluations for EtO. In addition to its industrial applications, EtO is used by healthcare institutions for sterilizing reusable medical devices before their first use or after prior use to facilitate reuse.

In this context, the document highlights the following key points:

- Scope of MDR: EtO cartridges and associated sterilization equipment are considered medical devices or accessories for medical devices under the MDR.

- Exemption from BPR: As per Article 2(2)(b) BPR, EtO cartridges used in healthcare institutions are outside the scope of the BPR due to their classification under the MDR.

Conclusion

In summary, the regulatory framework surrounding EtO sterilization is based on its applications across diverse contexts. For industrial manufacturing, EtO is governed under the MDR and IVDR, ensuring robust sterilization and validation processes without requiring additional assessments under the BPR. In healthcare institutions, EtO cartridges fall under the MDR, exempting them from the BPR while maintaining stringent safety and performance standards.

How Can RegDesk Help?

RegDesk is an AI-powered Regulatory Information Management System that provides medical device companies with regulatory intelligence for over 120 markets worldwide. It can help you prepare and publish global applications, manage standards, run change assessments, and obtain real-time alerts on regulatory changes through a centralized platform. Global expansion has never been this simple.